Radio remote control for crane & Industrial conveyor technology with receiver

- 6, 9 or 13 keys + Start/Stop

- Receiver with 12 or 20 relays

- Receiver with or without housing

- Two multi-stage joysticks or proportional two-axis joysticks

- Receiver with up to 36 relays

- Special components on request

Retrofitting remote controls for industry - remote controls for control and monitoring & Measurement

Radio remote controls are used in a wide range of applications across all sectors of industry. It is therefore essential for radio remote controls to be highly flexible and compatible so that they can be used across all sectors and retrofitted as easily as possible. And not only for Remote control of crane, cable winches, pumps & Co using a remote control.

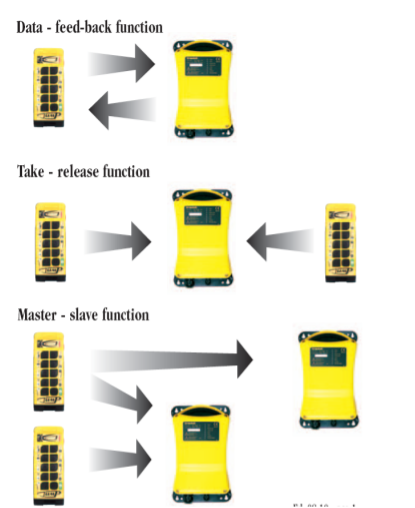

Thanks to bidirectional remote control and LCD display with 24-digit alphanumeric display and additional function symbols, our radio remote controls can also be used for measuring and reading messages and values. If the machine is equipped with an intelligent serial interface, the type and amount of feedback is virtually unlimited. In this case, a small programme can be used to generate messages directly from the machine. All common fieldbus networks such as CANopen, Profibus and Profinet are compatible.

Depending on the product range, our radio remote controls can be equipped with a maximum of two joysticks and up to 13 function buttons + start/stop. All remote controls are available as a set with receiver.

This makes it possible to perform a wide variety of tasks and control functions via radio remote control.

- Radio remote controls with toggle switches, joysticks & more

- Controlling the axles of a lorry trailer

- Control of forestry winches to pull felled trees out of the forest

- Application in the construction industry: Remote control of crane, concrete pump or construction hoist by remote control

- Operation of lifting devices and lifts

- Industrial automation: wireless radio remote control of machines allows you to work more safely and effectively and monitor and control automated processes via measurement via receiver and bidirectional remote control, e.g. via CANopen, Profibus and Profinet

- Intralogistics: In intralogistics, customers are constantly reporting damaged cables, e.g. on cable-operated conveyor belts. This can quickly become dangerous, especially in the area of the emergency stop function. A remote control with radio emergency stop is therefore not an option, but actually a must in intralogistics. We also offer customised solutions for controlling forklift trucks, storage systems and other applications in high-bay warehouses and the like

- In agriculture: Radio remote controls are ideal for remote control of the slurry pump, remote control for drag hose fertilisation or for irrigation systems, right through to remote control for your own tractor. Radio remote controls enable many control functions, from switching the pump on and off to precise control of a bale wrapper

- Further areas of application: Nautical engineering, access technology and transport

Each Industry is different and we know them all. Thanks to our decades of experience in the field of industrial machine control, we can offer you expert advice on site, by phone or via chat on our website and work with you to develop the perfect remote control solution for your needs. The high degree of flexibility of the modular system for our JUMP and Kappa radio remote controls & remote controls enables us to customise a wide range of buttons, switches, joysticks and other components to your requirements. We look forward to receiving your enquiry.

How do our remote controls for cranes work? & Machine control?

Industrial radio remote controls enable wireless and mobile control of machines, vehicles and equipment. The range, safety and reliability of the frequency, as well as the ergonomics of the buttons, joysticks and housing are therefore crucial for safe and efficient remote control. The components of the remote controls must also be highly resistant to water, oils, gases and extreme temperatures. But how exactly does all this work?

The principle is actually very simple: the transmitter sends encrypted data packets by pressing a button, a switch or turning a potentiometer. We work here with a 48-bit key for an individually encrypted connection between transmitter and receiver. The data packets are then first checked for the security code by the radio module in the receiver and then analysed in different ways. This means that a predefined task is carried out by the receiver as soon as it receives a signal from an authorised transmitter. With bidirectional remote control, the remote control also has a receiver for common fieldbus networks and can therefore receive information from the machine itself. Information can now be read on the 24-digit alphanumeric LCD display. Our remote controls work with the common operating frequency of 433 MHz (433,05 – 434,790 MHz).

The frequencies required for industrial radio remote controls may be used free of charge. But not all of them. Exactly which ones are free of charge can vary from country to country. Within the EU, most industrial radio remote controls operate in the 433 MHz or 868 MHz frequency ranges. However, many other radio waves operate on these frequencies, for example from mobile phones, W-LAN or communication for emergency services such as the police or fire brigade. Interference must be prevented at all costs, as this would have a serious impact on everyone involved. It was therefore decided that a specific frequency range may be used for each application and that a specific channel may be used within this frequency range, for example 433.05 MHz. This further restricts the transmission range. In addition, radio remote controls are equipped with a unique code and key so that the receiver only analyses signals sent by an associated transmitter.

Radio remote control with remote control & Joystick for the crane

In crane systems, any type of movement can be controlled with the pendant controls or radio remote controls from our programme. Thanks to the modular structure of the radio technology product range, the remote control can be customised for almost any machine. The same can be realised much more easily for the pendant control.

In many places, the days of complicated cab controls, which are still familiar from the cab of an old crane, are long gone. Numerous levers were required for the various types of movement in order to control each individual drive of the crane. Anyone who may have been fascinated by the toy crane as a small child would have been particularly taken with the numerous joints and the high degree of manoeuvrability. The real crane is even more versatile and therefore even more complicated to operate because the levers can be moved in different directions. You therefore always had to know exactly which of the many joints had to be operated in which order, for example to lower, lift or manoeuvre a load in a certain direction.

Fortunately, digitalisation is also finding its way into traditional machines such as cranes. Intuitive and ergonomic joysticks now make it much easier to move loads.

The individual drive units are controlled via radio remote control, for example. The crane operator will therefore be seen sitting in the cab less and less often. With the remote control in his hand, he can stand next to the crane and follow the movements from outside. This gives him a better overview.

The whole thing becomes even more efficient and easier with joystick control. Even with many remote controls, the principle has remained the same until now. The crane operator had to precisely master the assignment of the control levers and their interaction, similar to the cab control system.

Radio remote controls with joystick consist of a module with up to two joysticks, which can be expanded with additional switches and components. Joystick 1 is designed to execute the movements of the crane in the horizontal plane, while joystick 2 raises or lowers the load. The crane operator does not have to think much about this. If the joystick is pushed forwards to the right, the end of the crane also moves in the same direction, i.e. forwards to the right. The load can then be raised or lowered with the second joystick by the user pushing the lever away (upwards) or pulling it towards them (downwards). The decisive advantage: all crane drives are moved simultaneously and the individual joints no longer have to be controlled directly by the crane operator.

Radio remote controls from the JUMP series

The radio remote control of the Jump series can be used for many applications due to its good compatibility and small dimensions.

Special attention was paid to the safety functions, such as the stop button. This is controlled by 2 stop relays and a double microprocessor.

In terms of ergonomics and robustness, a great deal of development work was invested in the design of the hand-held transmitter to ensure an optimum combination of these aspects. The hand-held transmitter is fitted with a battery pack on the back, which can be easily replaced at any time. Each hand-held transmitter is also equipped with a 2-fold carrying strap.

The frequency and the automatic switch-off time can be easily changed using the operating buttons on the handset.

The receiver is available in 2 versions: one with a housing suitable for outdoor installation (IP65), the other for installation in a switch cabinet on a top-hat rail. An external antenna is included in the delivery.

Other special types of Jump radio remote control are available on request. The modular system leaves plenty of scope for highly customised adaptation of the control unit to your desired specifications. The labelling can of course be adapted to customer requirements.

Handheld transmitter

3 different sizes:

- 7 buttons (6 function buttons + start/stop)

- 10 buttons (9 function buttons + start/stop)

- 14 buttons (13 function buttons + start/stop)

Battery charger

2 different types:

- 220V AC

- 12 V DC

Receiving unit

2 different types:

- in plastic housing (IP65), suitable for outdoor installation, 12-20 relays

- Without housing, suitable for switch cabinet mounting, with top-hat rail mounting, 20 relays

Radio remote controls in forestry

One of the main applications here is the remote control of the cable winch with radio remote control to pull felled trees out of the forest by remote control. However, other machines in the field of timber harvesting are also suitable for radio remote control. For example, the control of skidders or typical crane control. Above all, the use on the forestry cable winch offers a decisive advantage: you can follow the movement of the tree trunk and at the same time maintain a safe distance. This allows you to react more quickly and is safe at the same time.

Radio remote control on the construction site

The main advantage here is the great flexibility of our modular system for remote controls. Many different machines and applications come together in the construction industry. Whether controlling a lorry with a concrete pump, a crane, a power unit or a lift – we work with you to configure the remote control for your specific application. Our products are used in pumps, winches, machines and more. One reason for this is the great flexibility in the design of the switches and joysticks.

Remote control of stacks and lifts

They are used everywhere: lifts and forklifts. Whether for storing goods in high-bay warehouses, transporting bricks or solar panels to the roof via an inclined lift, or for private removals. Operating a lift by remote control is a great help here. Wireless mobile control also eliminates a major weak point of many conventional lifts. The cabling. Lifts are frequently moved in daily use and a lot of movement is always particularly dangerous for one component: cables. Damage or cable breakage often occurs. Radio remote control solves this problem.

Radio remote control for conveyor belts and storage and retrieval machines

Efficiency and safety are crucial in intralogistics. After all, both are crucial to the success of your company. Logistics means movement and movement means wear and tear. And danger. Cable-operated conveyor belts are a frequent issue. Damage often occurs here. And a wireless emergency stop button is also an important component, especially in modern and automated warehouses or production facilities. Otherwise, employees can quickly find themselves in danger if conveyor belts, storage and retrieval machines, roller shutters or lever lifts malfunction. B-Command supplies the right radio remote control for all these areas.

Radio remote control in the field - why agriculture also benefits

Agriculture is certainly not the first area that many people think of when they hear the term “automation” or “remote control”. The image of the typical farmer with his tractor is too deeply rooted. But digitalisation is also becoming more and more prevalent here. The remote control of tractors, slurry pumps and irrigation systems offers decisive advantages in terms of safety and efficiency. And it’s not just the simple ON/OFF function of a pump that can be realised. For example, it is also possible to control a bale wrapper. After the baler has left the harvested straw or hay bale in the field, the bale is deposited from the loader onto the wrapping table of the so-called bale wrapper. The driver can now conveniently activate the wrapper from his cab and drop the bale onto the yard or field at the touch of a button as soon as it is well wrapped. An enormous time saving with little effort.

Radio remote control Kappa

- Up to 2 multi-stage joysticks

- Up to 5 buttons / toggle switches + start/stop

- Receiver with up to 36 relays

- Receiver with up to 8 proportional outputs

- Receiver with Housing in two sizes

- Range: up to 100m

- Weight of hand-held transmitter: approx. 1.4 kg

- Protection class IP65

- Operating temperature -20°C…+55°C

Do you have any questions?

SEND US YOUR MESSAGE

CONTACT INFORMATION

Follow us on our social media channels and be informed about new products.