Slip rings & rotary unions for industrial plants

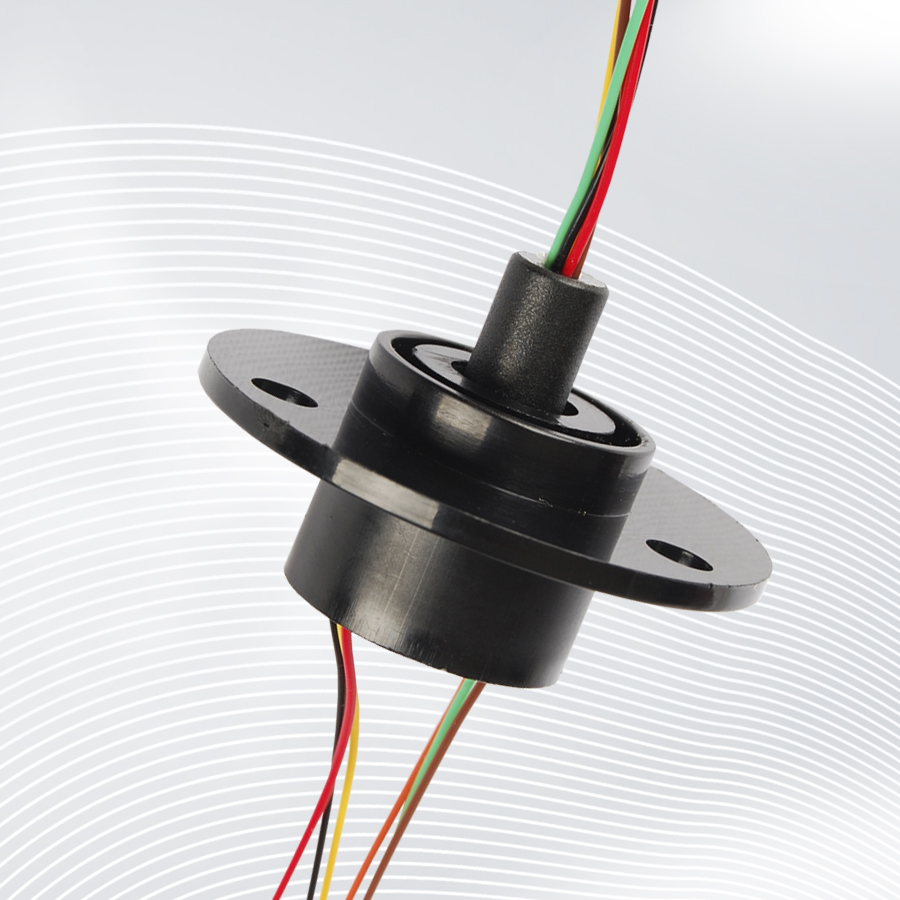

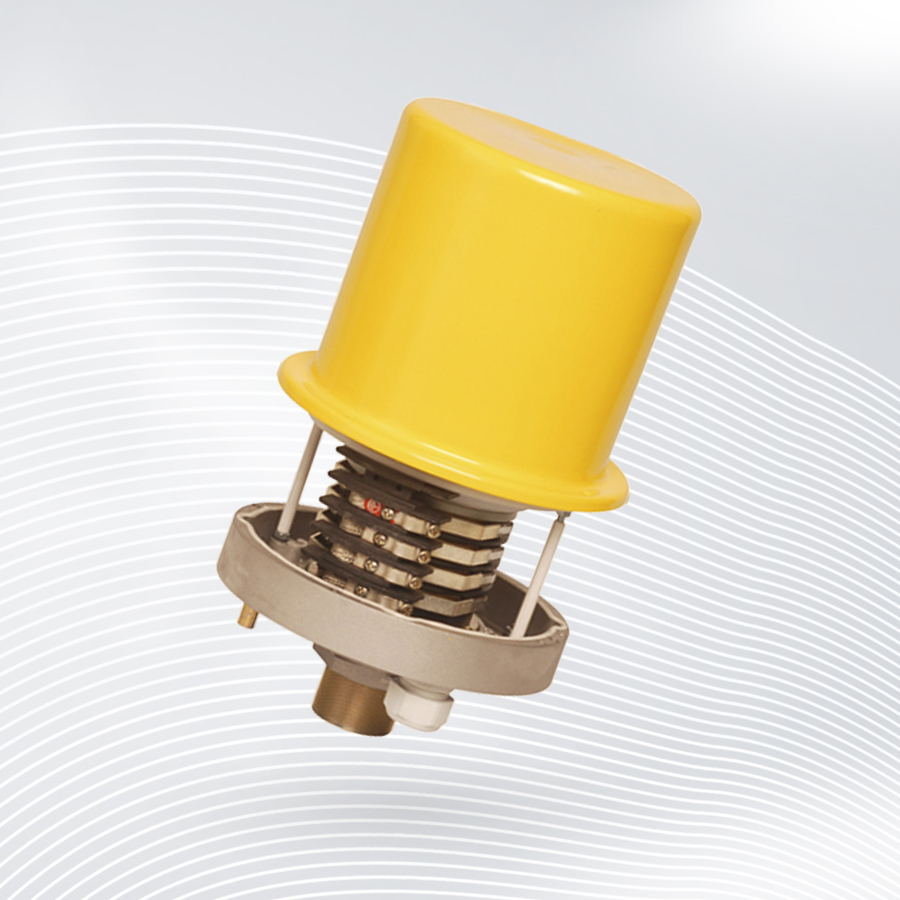

- compact slip rings

- Ø from 5,0…54,0mm

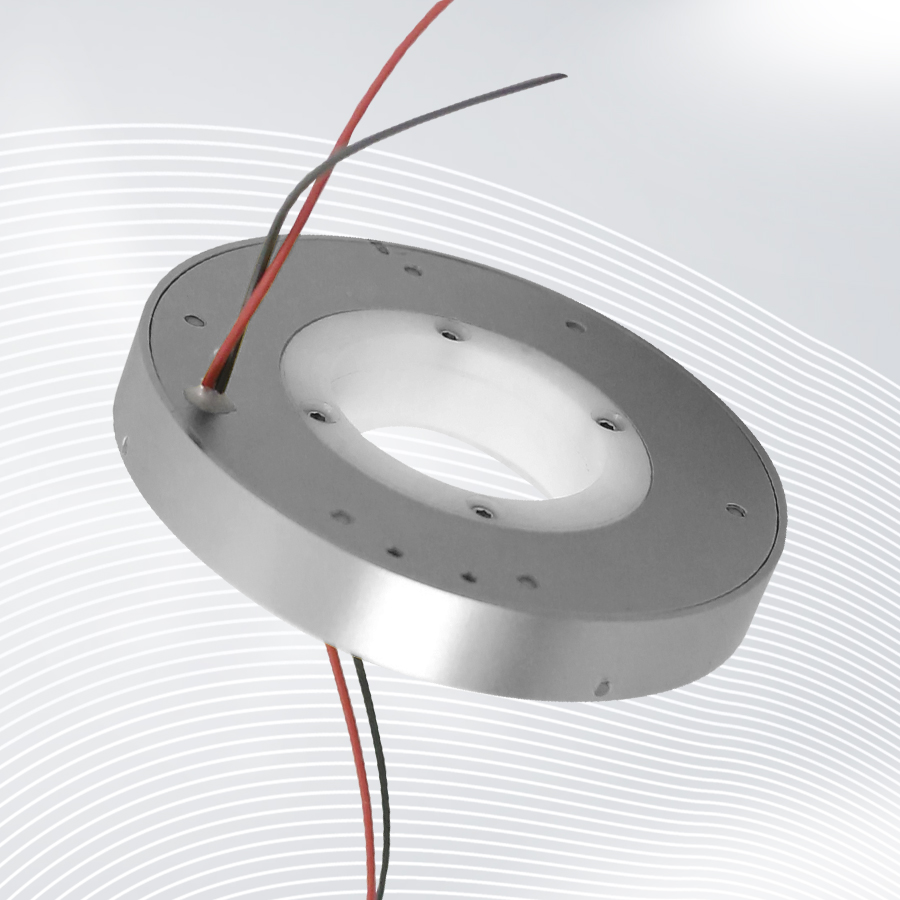

- Hollow shaft up to 300mm

- up to 144 rings

- 1-4 x pneumatics

- 6 or 12 rings

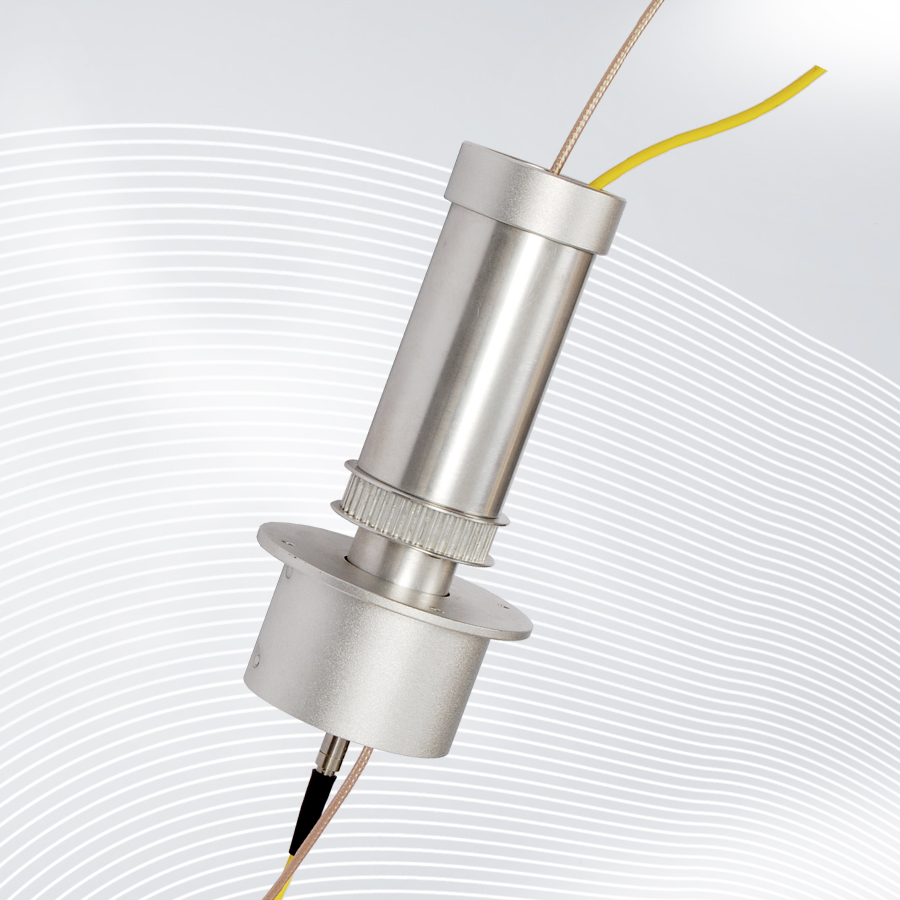

- 1-8 Fibre optic Transmission

- up to 1000 rpm

- 1-4 Coaxial conductors

- 2-72 Rings

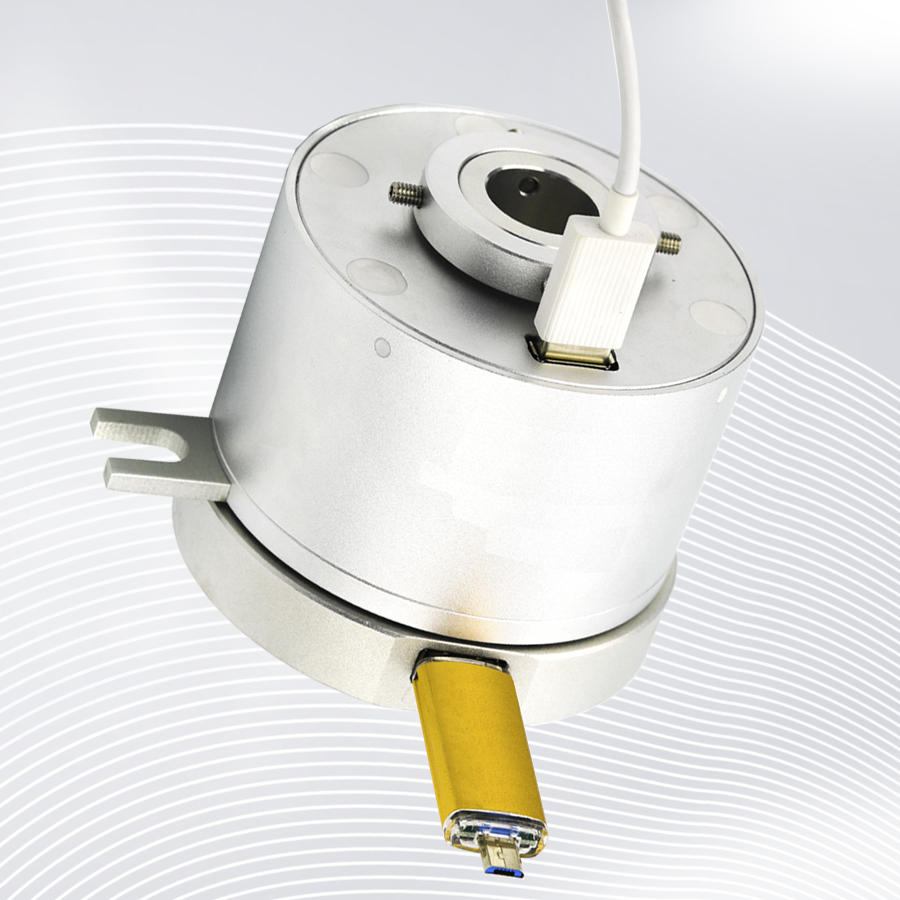

- 1 or 2 USB cables

- up to USB3.0

- HD-SDI transmission

- 2.5 GHz video signals

- 6-36 rings

- Plastic lamellar housing

- 6-15 sings

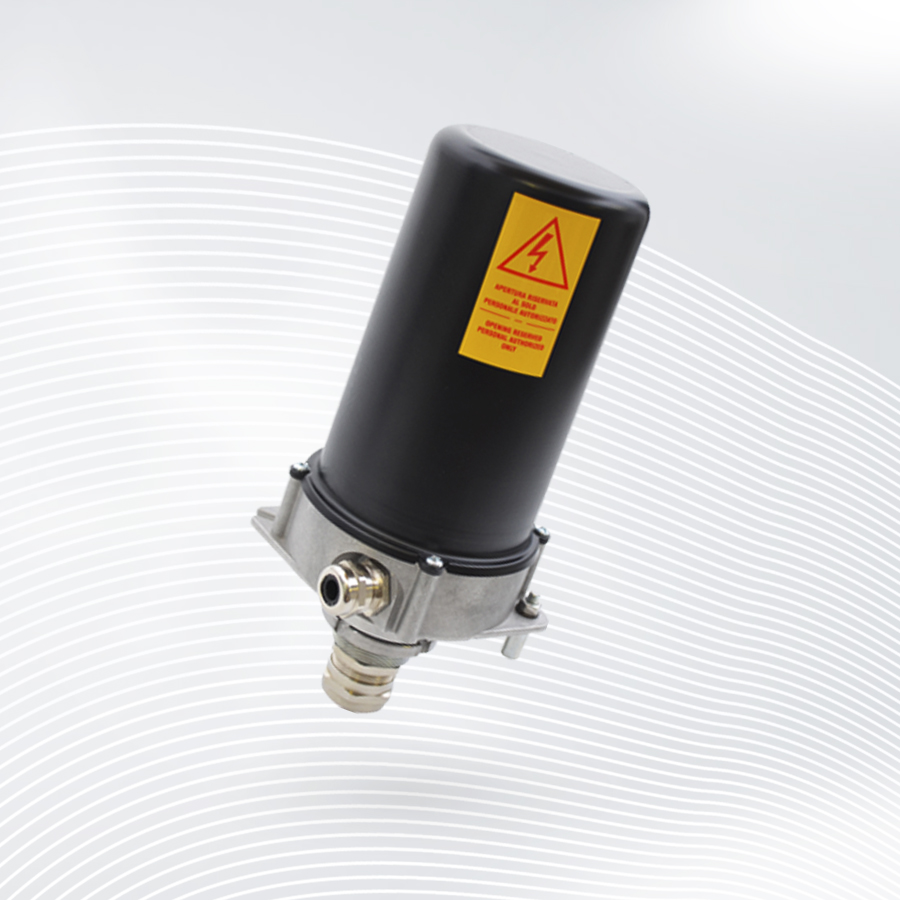

- aluminum housing

- 6-30 rings

- up to 50A per ring

- 6-24 Rings

- up to 100 rpm

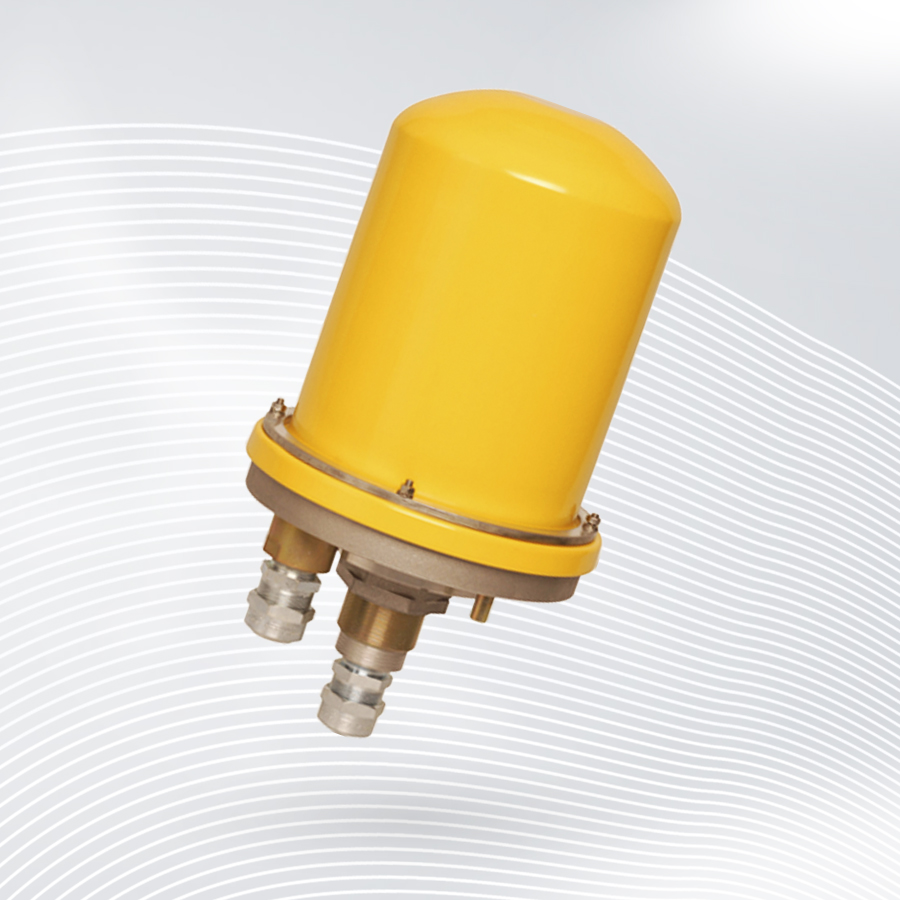

- ATEX approval

- 4-7 Rings

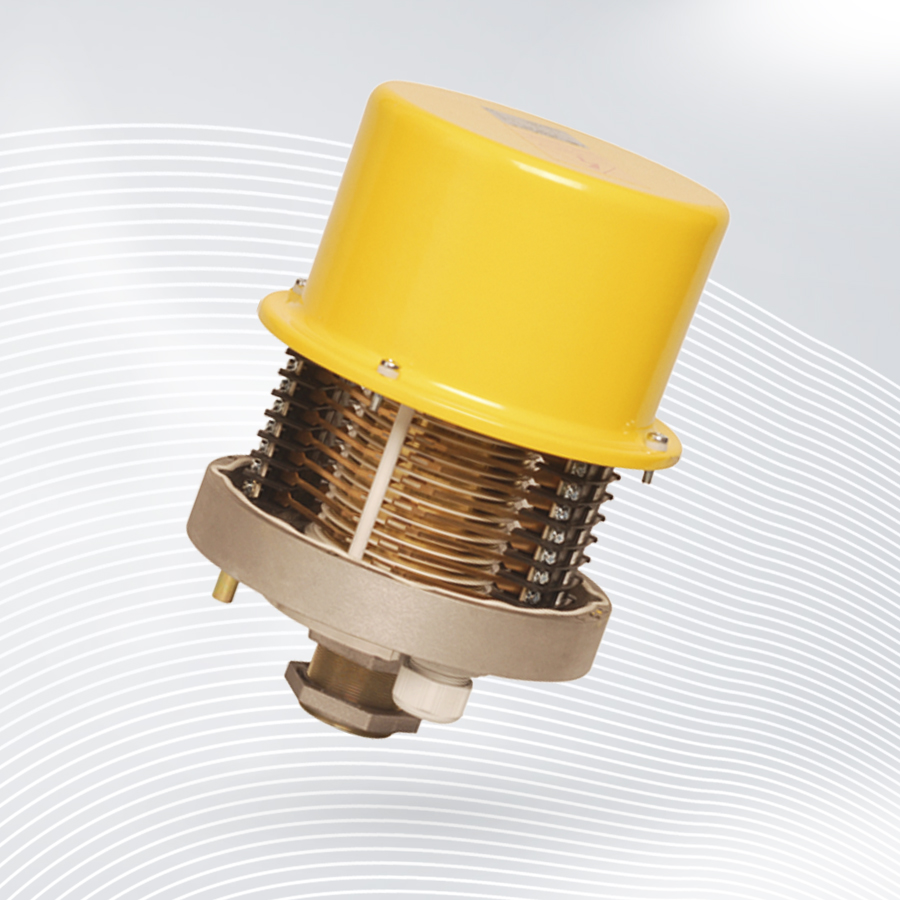

- 20-60 rings

- up to 100A per ring

- 18-42 Rings

- robust casing

- 4-14 Rings

- up to 120A per ring

- 4-36 Rings

- Hollow shaft up to 196mm

Slip rings for current and signal transmission during rotary motion

Slip rings are used to transmit electrical signals and to supply power between a stator – i.e. a non-rotating, stationary unit – and a rotor. For this purpose slip ring bodies are made of 3 or more graphite or steel contacts (brushes), which grind on 3 or more metal rings. The rotation of the metal ring then ensures continuous current transmission and electrical signal transmission without loss of power or data. Especially the signal transmission between rotating and stationary components is becoming increasingly important. This is because within the framework of Industry 4.0, the transmission of signals such as Ethernet, USB, RS, CANbus, video signals (optical channels), sensor signals and many more is becoming increasingly important. This is becoming more and more important for the precise control of fully automated and data-based industrial plants. Slip rings such as our encapsulated miniature slip rings, for example, allow space-saving and combined power and signal transmission.

Slip rings are essential electromechanical parts of commercial or industrial machines. They have to guarantee the transmission of data, media, energy and electrical power without noise and loss – sometimes under adverse conditions and extreme temperatures. This can only be achieved by combining technical know-how and targeted design processes. In addition to the selection of the best raw materials, professional production conditions, expert advice from our team and competent installation at the customer’s site.

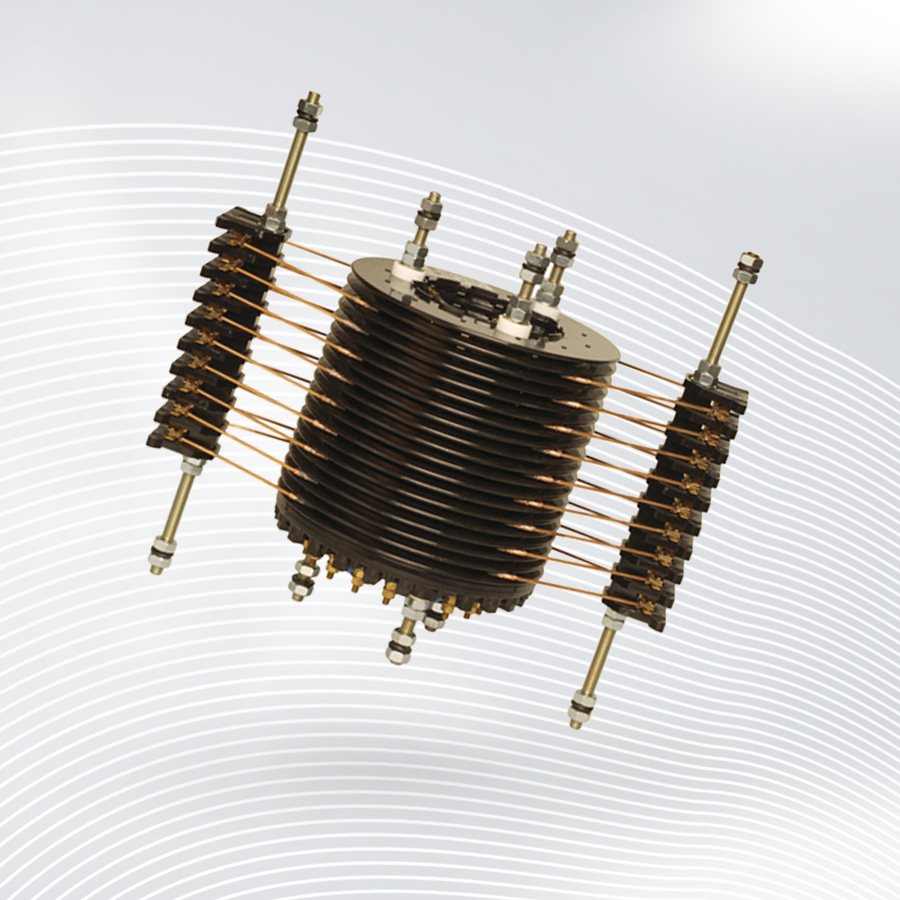

In order to meet all requirements, we can supply slip rings with aluminium housings, without housings, as well as with silver-to-silver and gold-to-gold sliding contacts. A slip ring consists of the five main components brush (sliding contact), conductor ring, ball bearing, rotor and housing. The brushes make a sliding contact with the conductor ring, which creates a rotating electrical connection. This conductor ring is mounted on the rotor, with the lead wires attached to the fibre brush and the inside of the conductor ring creating an electrical connection on each side of the slip ring body. Individually selectable are factors such as size, housing, channels, connection types, IP protection degree and materials of the sliding contacts.

Industry 4.0 on the move – just like our slip rings

Since numerous mechanical components are always in rotation, which makes fixed power transmission or even data transmission via cable impossible, slip rings are indispensable and almost maintenance-free and invisible electromechanical components. Only through intelligent design and high-quality materials can they guarantee not only loss-free, but also maintenance-free and fast power and signal transmission.

The ever faster and endlessly rotating data transmission of control signals, video signals and measurement data is becoming increasingly important. In addition to the standard power transmission or rotary transmission of fluids (e.g. hydraulic fluid or oil), gases and compressed air of classical slip rings.

Classical applications for wireless transmission of power & signals:

- Turning and slewing movements of a crane

- Filling plants

- Round scraper (sewage treatment plants)

- Hinged doors

- Dump truck

- 4K video image transmission

- Radar Systems

- Computer networks

- Support arm lights

- Wind turbines

- Packaging machines

- stage technology such as lifting platforms or even rides like roller coasters

You have questions?

SEND US A MESSAGE

CONTACT INFORMATIONS

Follow us on our social media channels and get informed about new products.