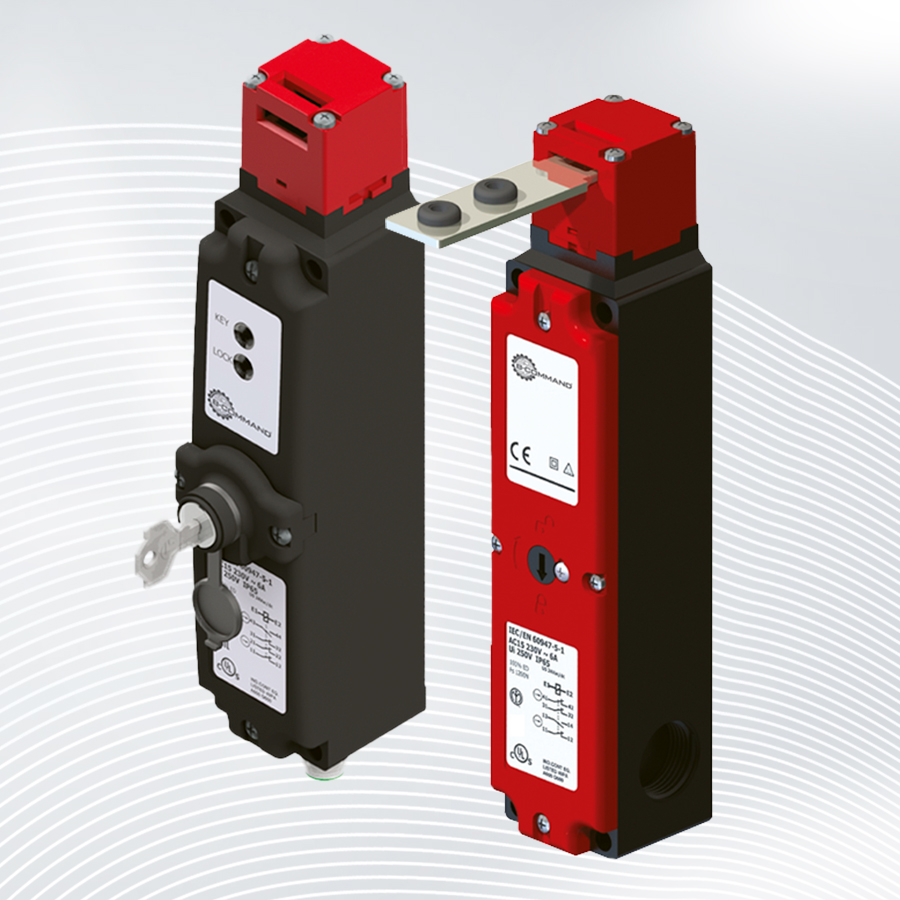

Safety Limit Switches

- Up to 4 slow action switches

- G20 cast iron housing

- Stainless steel housing possible

- Various circuit diagrams

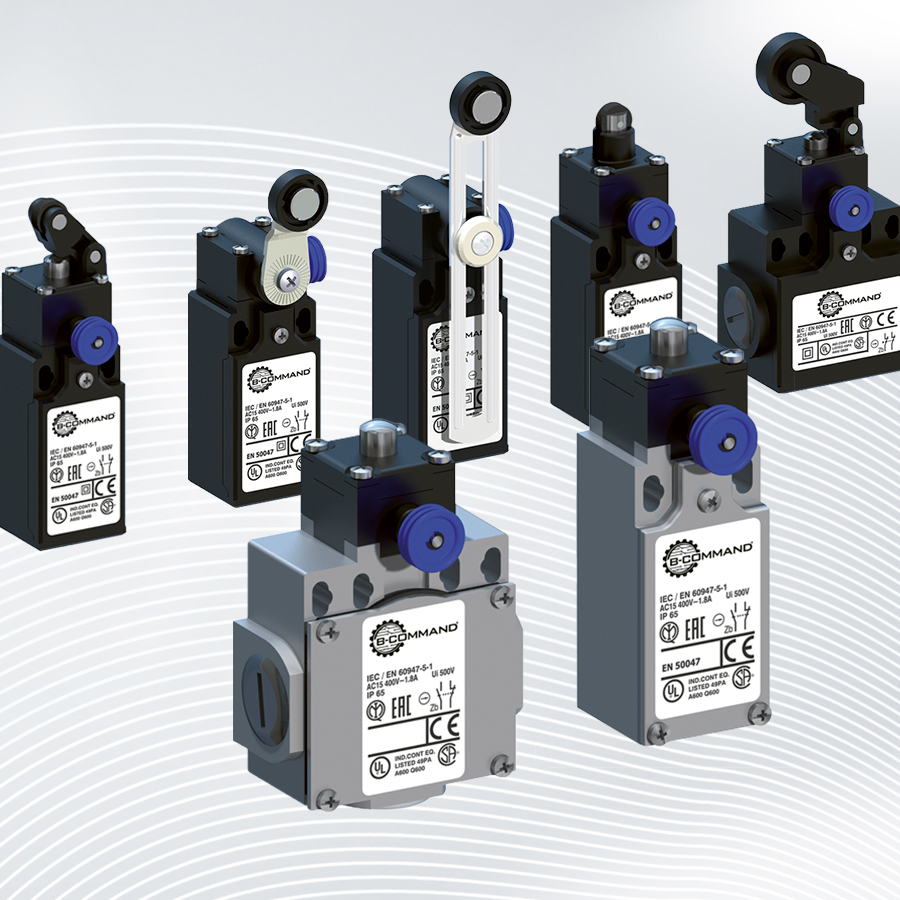

- Plastic or metal housing

- Adjustable / rotatable actuating heads

- Snap-action or slow-action switch

- Optional stainless steel shaft, various lengths

- Plastic housing

- With cable and/or plug

- Axial or radial cable outlet

- Slow action switch with 4 contacts

- SIL3, PLe, safety category 4

- Short or long design

- With cable and/or plug

- Up to 3 switching contacts

- Optional LED

- Plastic housing

- Short or long design

- With cable and/or plug

- Up to 3 switching contacts

- Optional LED

- Plastic housing

- RFID-coded actuator

- Adjustable / rotatable actuating heads

- Mechanical or electronic locking heads

- Metal housing

- Door handle for guard door protection

- In combination with safety limit switches

- Metal housing

- Adjustable / rotatable actuating heads

- Slow-action switch

- Optionally with reset button

- SIL3, PLe, safety category 4

- DIN rail mounting DIN35

- Up to 4 safety outputs

- Optional auxiliary contacts

- Plastic or metal housing

- Adjustable / rotatable actuating heads

- With cable and/or plug

- Snap-action or slow-action switch

- 6 different actuators

Safety limit switches - reliably control safety doors & machines

A safety switch is more than just a simple switch. It is a protective mechanism designed to save lives and prevent accidents. Whether you are aware of it or not, the special position switches (safety limit switches / safety position switches) play a crucial role in our daily lives and in every industry. Rapidly advancing automation means that more and more workpieces and machines are in motion without having to be controlled manually.

Nevertheless, it can always happen that people have to work on automation systems, for example for maintenance and repair, or enter areas where machines and devices work autonomously. If a person opens the safety door to such an area, or a protective bonnet or cover on a machine, whether due to an emergency or for routine maintenance and operation, the machines must be stopped reliably, safely and accurately. By the way, this does not only work with entire plants and machines. With the help of modern magnetic sensors, the positions of individual moving and potentially dangerous machine parts are also detected and, if necessary, stopped as soon as they have reached an individually defined end position. The signal can be transmitted in different ways, i.e. electrically, hydraulically, mechanically or pneumatically. With our safety limit switches, we rely on electromagnetic transmission.

And that’s not all. Likewise, limit switches can be used to control and monitor safety doors, on the one hand to prevent unauthorised access, for example with the help of RFID coding, and on the other hand to reliably measure when a safety door has been opened, for example by monitoring the position of a door handle to stop the machines in the safety area at the same moment.

We supply all components for the safe, simple and low-maintenance installation of safety limit switches. From individual sensors and safety hinges, to special door handles, to entire switches, pull-wire switches and magnetic switches with a separate trigger.

The advantages of our position switches

- Class II materials according to IEC 536: Doubling of the functional insulation to prevent electric shocks

- With positive break (snap action or slow action)

- Electrically separated contacts with contact blocks in dependent action and positive opening of the NC contacts

- Precision of the shift position

- Insensitivity to electromagnetic interference

- Use on sliding or rotating guards (covers, enclosures, doors, grilles, etc.)

- Optional RFID coding for reliable access control

These specific features make the limit switches ideal for monitoring and protecting industrial machines without inertia, where the downtime is less than the access time to the hazardous area. They thus contribute to the protection of persons working on dangerous machines by opening the control circuit. Pulling out the small latch (key) when opening the movable guard causes the machine drive to stop immediately.

The plastic series small latch (key) safety limit switches are made of glass-fibre reinforced UL-V0 and offer double insulation and a degree of protection of IP65.

The metal series safety limit switches are made of painted zamak and have IP66 protection.

All models are equipped with contact blocks 1NO+1NC, 2NC, 1NO+2NC, 2NO+1NC or 3NC with positive opening.

They comply with the requirements of the European directives (Low Voltage Directive and Machinery Directive) and meet all corresponding European and international standards.

EU standards & further requirements

International specifications:

- The International Electrotechnical Commission (IEC), which is part of the International

- standards organisation ISO, publishes IEC publications that serve as the basis for the

- serve for the world market.

European specifications:

- The European Committee for Electrotechnical Standardisation (CENELEC) publishes the EN

- Standards for industrial low-voltage equipment.

- These European standards differ only slightly from the international IEC standards and use a similar numbering system. The same applies to the national standards. Conflicting national standards are withdrawn.

Harmonised European specifications:

- The European Committees for Standardisation (CEN and CENELEC) publish EN standards for the safety of machinery.tions:

specifications in Canada and the USA:

- These are equivalent, but differ significantly from the IEC, UTE, VDE and BS specifications.

- UL: Unterwriters Laboratories (USA)

- CSA: Canadian Standards Association (Canada)

Note on the label issued by UL (USA):

Two levels of recognition of equipment are distinguished.

| Sign | Explanation |

|

„Recognized“: Approved for installation in a unit if the unit in question has been fully assembled and wired by qualified personnel. They are not valid for use as “general purpose products” as their possibilities are limited. |

|

„Listed“: Approved for installation in equipment and as a “general purpose product” also for separate sale as a component in the USA. |

European Directives:

The guarantee of the free movement of goods within the European Community presupposes the elimination of differences in the laws of the Member States. The European directives lay down common rules that are incorporated into the legislation of each state, while contradictory rules are repealed.

There are three main guidelines:

- Low Voltage Directive 2014/35/UE on electrical equipment from 50 to 1000 V alternating current and from 75 to 1500 V direct current. It specifies that the requirements set out therein are met if the equipment complies with the standards harmonised at European level: EN 60947-1 and EN-60947-5-1 for limit switches.

- Machinery Directive – 2006/42/CE: the main health and safety requirements for the design and manufacture of machinery and other equipment in the European Union, including safety components.

- Electromagnetic Compatibility Directive 2014/30/UE for all electrical equipment that may cause electromagnetic interference.

CE marking:

The CE marking must not be confused with a quality mark. It is proof of the conformity of the respective product with the European regulations. Thus, it is part of an administrative procedure and guarantees the free movement of the product within the European Community.

Standards:

- International standards:

- IEC 60947-1 Low-voltage switchgear and controlgear – Part 1: General rules (CEI EN 60947-1).

- IEC 60947-5-1 Low-voltage switchgear and controlgear – Part 5: Control circuit devices and switching elements – Section 1: Electromechanical control circuit devices (CEI EN 60947-5-1) – Chapter 3: Particular requirements for control circuit devices with positive break function.

- IEC 60204-1 Electrical equipment of industrial machines – Part 1: General requirements (CEI EN 60204-1).

- IEC 60204-2 Electrical equipment of industrial machines – Part 2: Designation of items and examples for drawings, diagrams, tables and instructions.

- IEC 60529 Protection classes of enclosures (IP code) (CEI EN 60529).

- European standards:

- EN 50041 Low voltage switchgear for industrial use. Control switch Position switch 42.5 x 80. Dimensions and features.

- EN 50047 Low voltage switchgear for industrial use. Control switch Position switch 30 x 55. Dimensions and features.

- EN 60947-1 Low-voltage switchgear and controlgear – Part 1: General rules.

- EN 60947-5-1 Low-voltage switchgear and controlgear – Part 5-1: Control circuit devices and switching elements – Electromechanical control circuit devices.

- EN 60947-5-5 Low-voltage switchgear and controlgear – Part 5-5: Control circuit devices and switching elements – Electrical emergency stop device with mechanical interlock function.

- American standards:

- UL 508 Standard for industrial control devices.

- 2 NO. 14-13 Industrial control equipment

- Chinese standards:

-

-

- GB 14048.5 Low-voltage switchgear and controlgear – Part 5: Control circuit devices and switching elements.

-

Functionality of safety limit switches

Class II materials according to IEC 536 are an important component of the position switches. The switches therefore have double insulation to eliminate the risk of electric shock and thus make other protective measures superfluous. No conductive part of the “double insulated” material should be connected to a protective conductor.

The positive break is also an important component of a safety limit switch. A control switch with one or more interrupter contacts has a positive opening operation when the switch actuator ensures full contact opening of the NC contact.

With regard to the electrical separation of the contacts, a positive drive, without elastic elements (e.g. springs), must exist between the moving contacts and the point of the actuating element where the actuating force occurs. The positive opening operation does not affect the NC contacts.

Safety limit switches with positive opening function can be equipped either with contact elements for snap action or slow action. To use several contacts on one position switch, they must be electrically separated from each other, otherwise only one may be used.

Where are safety switches generally used?

Safety limit switches and position switches are essential components of many industrial systems. They improve the safety, efficiency and accuracy of machines and systems. Here are some additional examples that highlight the many applications of these switches:

- Production lines: A safety limit switch is often used on production lines to control the flow of products. When a product reaches the end of the line, it activates the switch that stops the belt to prevent overflow and ensure worker safety.

- Automated warehouses: In automated warehouses, position switches can be used to control the position of storage robots. They detect when a robot has reached a shelf and send a signal instructing the robot to start or stop its action (such as picking up or placing an item).

- CNC machines: In CNC (Computer Numerical Control) machines, safety limit switches can help control the position of the tool head. You can stop the head when it reaches its maximum or minimum position to prevent damage to the head or the workpiece.

- Packaging machines: In packaging machines, position switches can be used to control the position of cartons or other packaging materials. They ensure that the packaging is started in the right place to ensure precise packaging.

- Oil and gas industry: In the oil and gas industry, safety limit switches can help to control the position of valves. They can detect when a valve is fully open or closed and then send a signal to stop or start the pump, contributing to the safety and efficiency of the installation.

These examples show that position switches can be used in a wide range of industries and applications. Their ability to provide precise position information and safely control machines makes them an indispensable component of many modern technologies.

Safety limit switches & sensors for doors

Safety limit switches play a decisive role in the function and safety of safety doors. Security doors are commonly found in industrial, commercial and even residential buildings and are used to control and secure access to specific areas. Here are some of the key functions that safety limit switches perform in relation to security doors:

- Door status monitoring: Security limit switches can monitor the status of a security door – whether it is open, closed or partially open. When the door reaches its end point (either fully open or closed), it activates the end safety switch, which sends a signal to the control system to update the status.

- Preventing overrun: Safety limit switches can help prevent overloading of the door drive mechanisms. When the door reaches its end position, the switch sends a signal that stops the motor to prevent it from continuing to run and possibly overheating or being damaged.

- Burglary protection: In some cases, safety limit switches can serve as part of a burglary protection system.overheated or damaged. If the door is forced open, the switch can send a signal to an alarm system to trigger an alarm and/or notify security.

- Safety interlock: Safety limit switches can also function in conjunction with a safety interlock. When the door is moved to the closed position, the end security switch activates an interlock that prevents the door from being opened without the correct authorisation.

- Integration into safety systems: Safety limit switches can be integrated into comprehensive safety systems. They can help monitor the status of the door and can be coordinated with other security devices such as cameras, motion sensors and access control systems.

In summary, safety limit switches play an important role in the security and control of security doors. They help to ensure door security, control access and minimise potential security threats.

Our range: Switches & Accessories

Our range: Switches & Accessories From safety switches, tumblers and sensors to door handles, hinges and pull-wire switches. This allows you to tailor your security installations to your individual needs, operating procedures and access rights for employees (for example, with the help of RFID).

Safety switch with separate release

Safety switches that can be actuated separately are found in many areas of production. They are particularly useful for guards that can be removed, moved sideways or rotated. These switches ensure that the workplace is only safe when they are in the closed position. They are often found in machine tools, where it is often necessary to access dangerous areas in order to operate the machine.die Maschine zu bedienen. These safety switches can also be retrofitted to existing profiles.

Safety switches that can be actuated separately are found in many areas of production. They are particularly useful for guards that can be removed, moved sideways or rotated. These switches ensure that the workplace is only safe when they are in the closed position. They are often found in machine tools, where it is often necessary to access dangerous areas in order to operate the machine.die Maschine zu bedienen. These safety switches can also be retrofitted to existing profiles.

With safety switches of this type, the various parts are not firmly connected to each other (design 2), but are only brought together when the switch is actuated. Opening the safety door disconnects the actuator from the rest of the unit. This causes certain contacts in the safety switch to open automatically and others to close.

This device is useful to ensure the safety of the operator in machines where dangerous conditions due to the mechanical inertia of moving parts, pressurised components or high temperatures continue for some time after the stop signal has been generated.

This device, when used individually, is not suitable for applications in machines where the operator can enter the protected area with his whole body, as there is a possibility that the safety guards will be closed accidentally after the operator has entered.

To test for proper operation, the correct insertion of the actuator must be checked. Start the machine with the guard closed. In this condition it must be impossible to open the guard. It must not be possible to start the machine when it is stopped and the protective device is switched off.

Safety hinges

In the field of safety devices, B-COMMAND has developed a new hinge with multiple integrated circuits, suitable for all applications where high safety is to be combined with a modern and refined design.

In the field of safety devices, B-COMMAND has developed a new hinge with multiple integrated circuits, suitable for all applications where high safety is to be combined with a modern and refined design.

When it comes to monitoring rotating guards, various options are available. In addition to the usual safety switches, safety sensors and position switches, there are also hinge safety switches. These special safety switches are very practical for safeguarding hinged doors and service flaps, whether small or large, light or heavy. They are compact, unobtrusive and therefore ideal for machines and systems where design plays an important role.

One model of this kind is the SC-HI series.ne important role. With hinge safety switches, the safety function is triggered by a built-in cam as soon as a certain angle is reached. This fulfils the requirements mentioned in EN ISO 14119. Since the safety switch itself serves as a hinge, an additional component can be saved. The security function is concealed in the hinge, which offers a high level of protection against manipulation. This allows a compact design with convenient access to the machine’s working area without the need for a switching element on the opening side of the safety door.

Thanks to its small dimensions and the numerous mounting and connection options (cable/plug), the unit can be easily installed on most common aluminium profiles (minimum width 30 mm). Installation is also facilitated by the integration of a safety switch in a single enclosure, avoiding the need to separately install a mechanical hinge and a safety switch connected by a special pin.

The use of stainless steel components and IP67 protection allow the hinge to be washed frequently and used in environments where cleanliness and hygiene require the utmost attention.

The B-COMMAND hinge has been designed and manufactured according to the rules of the international IEC publications and the applicable European EN standards; the use of a redundant system and a suitable configuration make it possible to obtain a safety system for machines up to SIL 3 or PLe according to EN ISO 13849-1.

Both the self-extinguishing hinge body and the pivot are made of high-strength technopolymer that is resistant to solvents, oils, greases and various chemical substances. The internal switch consists of 4 double break contacts with slow action. Positive opening (according to IEC EN 60947-5-1) is guaranteed for all NC contacts. All circuits have low contact resistance, thanks to the self-cleaning effect of the silver pastes.

Each hinge is supplied with the following set

- °4 Technopolymer covers (to prevent free access to the screws).

- n°4 Technopolymer bushes (for hexagon socket or nut M6)

- n°2 safety plugs in thermoplastic elastomer to ensure IP67 protection.

Electromagnetic safety limit switches (optionally with RFID)

Magnetically triggered safety switches have an electric coil that generates a magnetic field as soon as current flows through it. When it reaches a certain strength, the switch is triggered and the circuit is interrupted. As soon as the magnetic field reaches a certain strength, the switch is activated and the circuit is interrupted. They are reliably used for machines with frequent operation and vibrations.

Magnetically triggered safety switches have an electric coil that generates a magnetic field as soon as current flows through it. When it reaches a certain strength, the switch is triggered and the circuit is interrupted. As soon as the magnetic field reaches a certain strength, the switch is activated and the circuit is interrupted. They are reliably used for machines with frequent operation and vibrations.

The SC-EMP3 / P4 device is supplied with a coded actuator with RFID technology. The supplied actuator has been coupled to the unit by the manufacturer and is therefore ready for use.

The actuator to be used is unique, it is possible to pair other devices, but each new paired actuator replaces the previous one. The actuating head cannot be disassembled by the user, so we recommend selecting the correct actuating head before purchasing the product.

The actuator supplied is a high coding level actuator according to the EN ISO 14119 standard, so the measures against a simple bypass strategy for low coding level devices are not required.

Magentic safety sensors

Magnetic safety sensors are very useful for machines that generate a lot of dust or dirt, or in areas where hygiene is particularly important, such as food machinery.soren

Magnetic safety sensors are very useful for machines that generate a lot of dust or dirt, or in areas where hygiene is particularly important, such as food machinery.soren

In combination with a suitable safety module, the magnetic SC-MS sensors guarantee a safety system with Safety Integraty Level (SIL CL) up to SIL 3 (according to EN 62061) and Performance Level up to PLe (according to EN ISO 13849-1).

- Sealed: insensitive to dirt.

- Wide operating range.

- Difficult to circumvent as they can be easily hidden (with non-magnetic material).

- Electrical output contacts: 2NC, 1NO + 1NC or 1NO + 2NC.

- Optionally equipped with LED display.

- Intervention from all directions.

Safety limit switch with interlock & reset

Limit switches with interlock and manual reset are equipped with actuating heads with plunger, roller plunger or roller lever to detect straight or angular movements. The plastic series are made of glass fibre reinforced UL-V0 thermoplastic and offer double insulation and IP65 protection.

Limit switches with interlock and manual reset are equipped with actuating heads with plunger, roller plunger or roller lever to detect straight or angular movements. The plastic series are made of glass fibre reinforced UL-V0 thermoplastic and offer double insulation and IP65 protection.

The metal series are made of a zinc alloy (Zamack) and have a degree of protection of IP66.

The limit switches with interlock and manual reset are equipped with 1NO+1NC, 2NC, 1NO+2NC, 2NO+1NC or 3NC contact blocks with positive opening of the NC contact(s).

After actuating the control unit and exceeding the locking point, the NC contact(s) remain(s) in the open position. The return to the original operating state only takes place by deliberately pressing the reset button.

Special features:

- Visible operation (error storage)

- Power switching capability (conventional thermal current 10 A)eller thermischer Strom 10 A)

- Contact blocks with positive opening of the NC contact(s) “N.C.” (symbol )

- Electrically separated contacts

- Precision of the switching positions (consistency)

- Insensitivity to electromagnetic interference

These special features make the limit switches ideal for detecting and monitoring faults in hoists, electric lifts, goods lifts, escalators, conveyor belts, etc.

They keep track of the position of the machine parts and can even signal when a new work step starts or is finished.

Lockable metal door handles

Our locking handles can be adapted to all types of safety doors, even with profiles of different thicknesses. Slots and multiple mounting holes allow full adjustment of the base and ensure compatibility also with customised solutions.

Our locking handles can be adapted to all types of safety doors, even with profiles of different thicknesses. Slots and multiple mounting holes allow full adjustment of the base and ensure compatibility also with customised solutions.

The possibility of adjustment to three axes allows enormous flexibility and smooth use. The handle can be combined with any interlocking device of the SC-EMP safety guard as well as with limit switches with separate actuator.

Thanks to the M12 connection of the locking device, installation is simple and fast. In addition, the metal handles are very robust to withstand high mechanical loads.

The 4 mm thick base used ensures very good corrosion resistance, making the handle suitable for most industrial applications. The grub screw with ball allows regulation of the pull-out force (from 20 to 140N).

In this way, they combine safety switch and door handle and make the operation of your machines safer and more comfortable. With our door handle actuators you improve the ergonomics of your installations and reduce the installation effort. The machine operator can conveniently release the interlock of a safety door at the handle without having to operate an external switch. And if you wish, even an EMERGENCY STOP button can be integrated.

Our range is versatile: whether electromechanical or contactless actuators with door detection sensor, solutions for walk-in hazardous areas or compact combinations of door handle and safety sensor – we have the right product for you.

Pull-wire switches for doors, flaps and covers

The easy-to-use limit switches for safety applications with rope (pull-wire switches) with emergency stop offer specific features:

The easy-to-use limit switches for safety applications with rope (pull-wire switches) with emergency stop offer specific features:

- Ability to switch heavy current (conventional thermal current 10 A)

- Contact blocks with positive opening of the NC contact(s) “N.C.” (symbol )

- Electrically separated contacts

- Precision of the switching positions (consistency)

- Insensitivity to electromagnetic interference

The use of B-COMMAND pull-wire safety switches allows you to reduce the need to install multiple emergency stop stations at different locations on the machine.

Pull-wire safety switches, also called emergency stop pull-wire switches, are safety devices used in industrial applications to quickly and efficiently shut down machinery when a hazard is detected.

The mechanism of the pull-wire safety switch is simple: a wire attached to the switch extends along the danger zone. If someone pulls the rope or it is activated by another movement, it actuates the switch and triggers an emergency stop.

The advantages of pull-wire safety switches are:

- Extended coverage: A pull-wire safety switch can cover a larger danger zone than other safety switches. This is particularly advantageous in elongated installations such as production lines or conveyor belts.

- Quick emergency stop: In case of emergency, the pull-wire safety switch enables quick and easy actuation of the emergency stop. Staff can pull the rope from any point along its length to stop the machine immediately.

- Flexibility: They are flexible in their application and can be mounted both horizontally and vertically, depending on the specific requirements of the machine or plant.

- Safety: They increase safety in the workplace by providing an effective and immediate way to shut down machines in case of danger.

- Robustheit: Seilzug-Sicherheitsschalter sind robust und widerstandsfähig gegen raue Industrieumgebungen, was ihre Lebensdauer verlängert.

These switches are essential in a wide range of industrial applications and help to minimise accidents in the workplace while ensuring compliance with safety standards.

Do you have any questions?

SEND US YOUR MESSAGE

CONTACT INFORMATION

Follow us on our social media channels and be informed about new products.